Home > Products > Biocide & others products

Home > Products > Biocide & others products

Product Category: Intermediates/Other intermediates

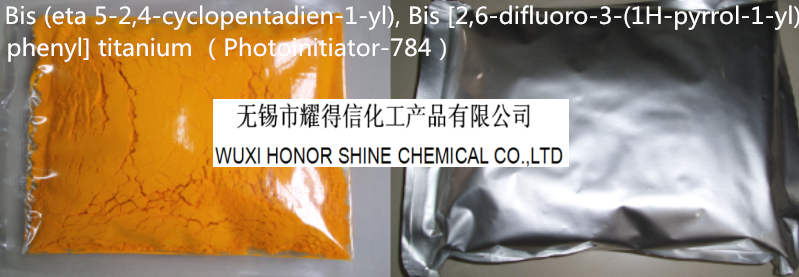

Synonyms: Bis (eta 5-2,4-cyclopentadien-1-yl), Bis [2,6-difluoro-3-(1H-pyrrol-1-yl) phenyl] titanium

CAS NO: [125051-32-3]

Molecular Formula: C30H22F4N2Ti

Molecular Weight: 534.37

Product Purity: ≥ 99% (wt) liquid chromatography

Appearance: orange yellow powder

Melting Point: 160 ~ 170 ℃ (DSC method)

Clarity: clear (methyl ethyl ketone solution)

Hazard Symbols Codes:F,Xn,N

Risk Codes:36/37/38-51/53-62-48/22-11

Safety Codes:26-36/37/39-61-36/37-33-22-7

TSCA : Yes

UV Curing Range: effective absorption peak of 390、460 nm, and absorption to 500nm

Packing: The inner packing is plastic film bag and Aluminum foil bag (net weight of 500g or 1,000g), while the outer packaging can be boxes, barrels and bags.

Purposes: This product is a UV curing agent mainly used for UV curing of alkyd resins,acrylic resins, silicone resins, epoxy resins, etc.. Since the decomposed products of the product

during the curing process is colorless or white, it can be both used for the light colors and dark colors, and it also has light bleaching effects. The detailed applications are as follows:

1. UV Paints

It can be widely used in the production of plastic, vacuum plating, PVC floorings, mask plates,

automobile headlights, wood floorings, cabinet panels, etc.. The curable resins include epoxy acrylate, urethane acrylate, polyester acrylate, polyether acrylate, polyacrylic resin and unsaturated polyester, etc., as well as a variety of monofunctional and multifunctional acrylates.

The adding dosage: used alone or in conjunction with other photoinitiators, the recommended dosage is 0.3-3% (wt/wt).

2. UV Inks

UV ink has the following advantages:

1) does not contain any volatile organic solvents, little pollution, without compromising human health, 100% solids, there is no inconsistent thickness of printing films at the front and rear brought about by solvent evaporation;

2) the ink does notblock the network, which is conducive to fine products printing;

3) during the printing process, there is no need to worry about the damage to substrate caused by the solvent, the ink quality is stable, the dry ink films have very good gloss, and the ink has excellent wear

resistance, water resistance, oil resistance and solvent resistance;

4) The ink can be instantly dried, the printing production line can be organized quickly, which can greatly improve theprinting efficiency;

5) Ink-saving, a kg of solvent-based inks can print about 50 ㎡ , while the UV inks can print 70 ㎡ under the same working conditions.

UV Inks will be used much more frequently in the advertising and banner printing industry.UV inks have been developing very quickly, and more and more printing factories are beginning to use new type UVdigital printing inks. While using, Photoinitiator-784 can be mixed with ink prepolymer to prepare UV ink, the adding dosage is about 0.3% to 3%, it can also be used in conjunction with other curing agents. The advantages of using Photoinitiator-784: it has deep curing

effects and can give full play to the beautiful colors of the inks.

3.UVA dhesives

UV adhesives are mainly used for bonding of the products such as industrial, glass crafts,

crystal handicrafts, electronic components (liquid crystal sealing of LCD, fiber optic connectors, touch panels, SMD, LED, reinforced sealing adhesives for electronic cables, EMI, VCD discs, laser heads, touch screens, cameras, optical lens, buzzers, speakers, etc.), the watch industry, glass furniture, glass- stainless steel, glass-aluminum, plastic products (PVC,

PS, ABS) and so on. The advantages of using Photoinitiator-784 curing agent are as follows: fast curing,

high transmittance.

4.Photoresists

Photoinitiator-784 can be used as negative photoresist, it is suitable for production of low-integration devices.

5. Photo polymer Printing Plates, Composite Materials, Dental Fillings, etc.

苏公网安备32020602001579 Technical:XUNCEN

苏公网安备32020602001579 Technical:XUNCEN